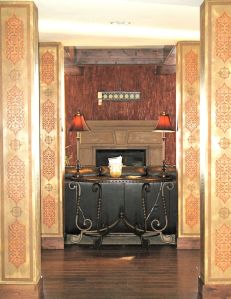

This is a project we recently completed using Stampino impressions/contours designed by artist Ron Hansen. We saved a lot of money using the impressions/contours by not having to buy expensive vinyls to complete the project. In total we needed 64 of these patterns which could have added big dollars to this project. Using the re-useable impressions we were able to execute this project using only three impressions and one contour for a cost of about $45.00. Ok now lets get to the Pro’s and Con’s:

Pro’s

1. Well that’s an easy one. Money saved by using the stencil impression vs. using an expensive vinyl.

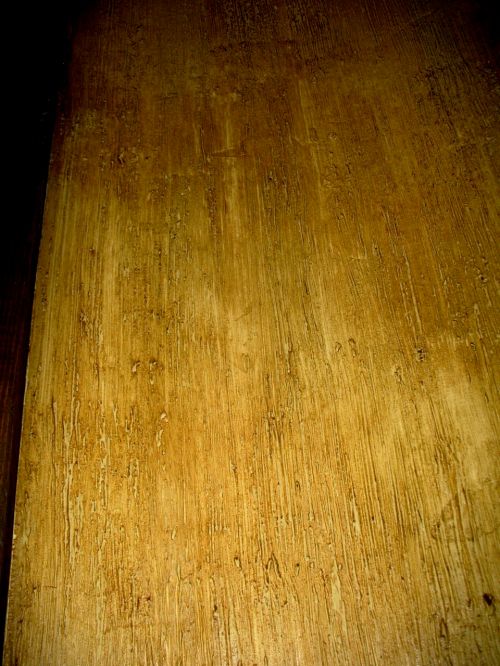

2. We only used three impressions on the whole job and they held up nicely and are now ready for use again. We troweled a lot of lusterstone through the impressions. Washed and cleaned nicely without tearing or ripping.

3. I was pretty amazed at how fast we were actually able to execute. I really thought it would have taken a lot longer to complete.

4. Designer & Client were happy, happy, happy! Yeah…I think she’s ready for more.

Cons

1. Other than the fact that I have very little patience, I really can’t think of any con’s that I felt strongly about. I just couldn’t wait to see the end result!! Possibly the fact that the impressions needed to be washed after each use, but because we had three of them going it really wasn’t that big of a deal and certainly not enough to keep me from doing this again. I judge a lot of projects on “ease of application” on whether or not I will do it again. I give this one a thumbs up!